PetroGuard

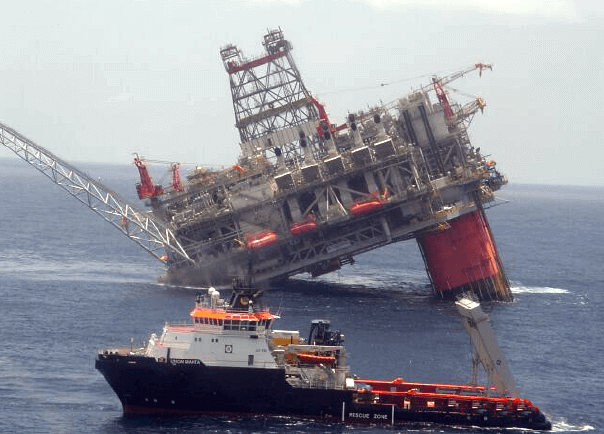

Oil spills solidifying absorbent that floats on water

Key features of the absorbent are:

|

• Hydrophobic |

|

• Non-toxic or polluting |

|

• Oleophilic |

|

• Super-absorbent |

|

• Non-catalytic activity |

|

• Will not release under pressure |

Example organics absorbed and immobilized

| Crude Oil | Heating oils |

| Diesel oil | Gasoline |

| Kerosene | Machine oil |

| Polynuclear aromatic hydrocarbons | Hydraulic oil (not synthetic) |

| Chlorinated hydrocarbons | Jet Fuel |

PetroGuard’s capacity depends upon the active material to selectively absorb molecules with suitable solubility characteristics, directly into its internal structure. This allows the polymer to absorb very large quantities of target molecules. The molecules are partitioned into the polymeric regions of the absorbent. PetroGuard has an exceptional affinity for non-polar organic compounds. Once the process has taken place, PetroGuard will form an interlocking network matrix with a rubber-like consistency. Extreme temperatures my affect the absorption process: very cold oil will absorb more slowly than warm oil.

PetroGuard is ideally suited as an emergency spill response absorbent because of its rapid immobilizing characteristics. PetroGuard will prevent or reduce production of vapors from volitile petroleum products. Absorbed materials are then easily handled and disposed of as a solid, preferably by incineration.

PetroGuard is also an ideal product for the control of liquid hydrocarbons during industrial maintenance procedures, such as occur in refining facilities.

For water applications, the primary function of PetroGuard is to prevent further migration of any spilled, un-dissolved or floating product. PetroGuard-D can be applied in its “free form” directly to the spill either manually or with mechanically assisted devices.

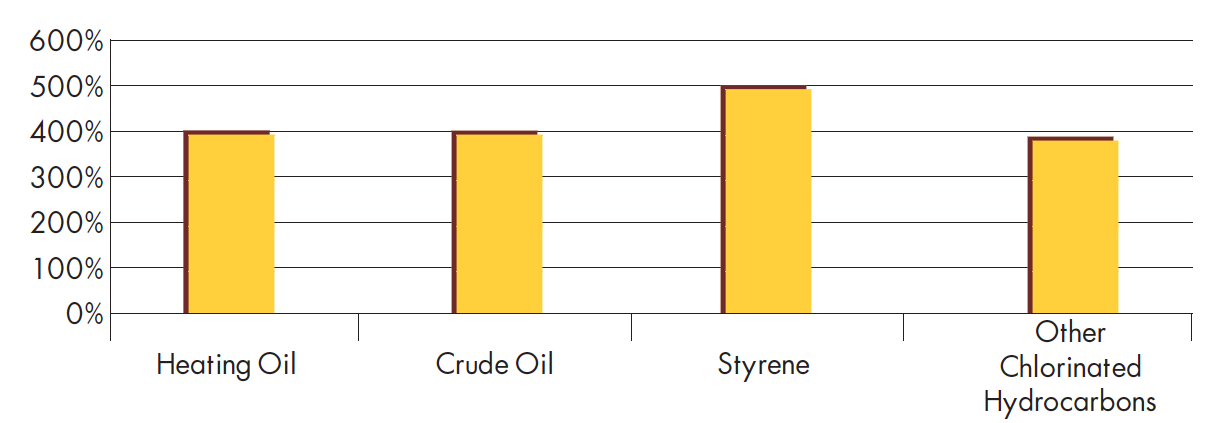

PetroGuard’s weight to weight capacity in field applications can vary depending on the method of application, amount of spilled liquid or the presence of other chemicals or surfactants.

In situations where the danger of inadvertent spills exists, adequate stores of PetroGuard is recommended as an ideal component of established emergency response program. Because of PetroGuard’s rapid immobilizing characteristics, it is an ideal product for quick response situations. It is the ideal product for hazardous as well as for many appropriate non-hazardous spill applications. PetroGuard is listed in the 2004 SEHSC Emergency Response Manual as “Polymeric Absorbing Deactivating Powder”.

Spent PetroGuard is best disposed of by incineration. Its high BTU value makes PetroGuard an excellent candidate for fuel blending. PetroGuard has a BTU content more than 19,000 BTU’s per pound, with very little ash residue.

Depending on leaching test (TCLP) requirements, spent PetroGuard may also be land filled. However, specific regulations and analytical documentation for landfill disposal should be obtained from the appropriate regulatory agencies (local, state and/or federal). Certain types of cleanup applications may result in the classification of the spent materials as hazardous. In such instances, the material should be disposed of through an approved hazardous waste disposal service with the appropriate documentation

PetroGuard should be stored in temperature conditions less than 536 degrees F. and has an indefinite shelf life.

The Material Safety Data Sheet (MSDS) indicates PetroGuard is non-toxic and non-hazardous based on current regulatory standards. Other regulations may apply for specific applications.

Toxicity testing on fish indicates practically non-toxic, LC/EC/IC 50>1000mg/l .

|

MATRIX STRUCTURE |

ORGANIC POLYMER |

|

PHYSICAL FORM |

WHITE |

|

PARTICLE SIZE |

20-60 MESH |

|

MOISTURE CONTENT |

<0.5% |

|

APPARENT DENSITY LB/CF |

14.5 |

|

ASH CONTENT (%) |

<0.01 |

|

FLASH POINT |

NOT APPLICABLE. |

|

MSDS |

AVAILABLE UPON REQUEST |

Warning: Oxidizing agents such as concentrated nitric acid attack organic polymers under certain conditions. This could lead to anything from slight degradation to a violent exothermic reaction. Before using strong oxidizing agents, consult sources knowledgeable in handling such materials.

Notice: No freedom from any patent owned by Seller to others is to be infringed. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal practices are in compliance with applicable laws and other governmental enactments. Seller assumes no obligations or liability for the information in this document

Loading Capacities by Weight (Weight to Weight)